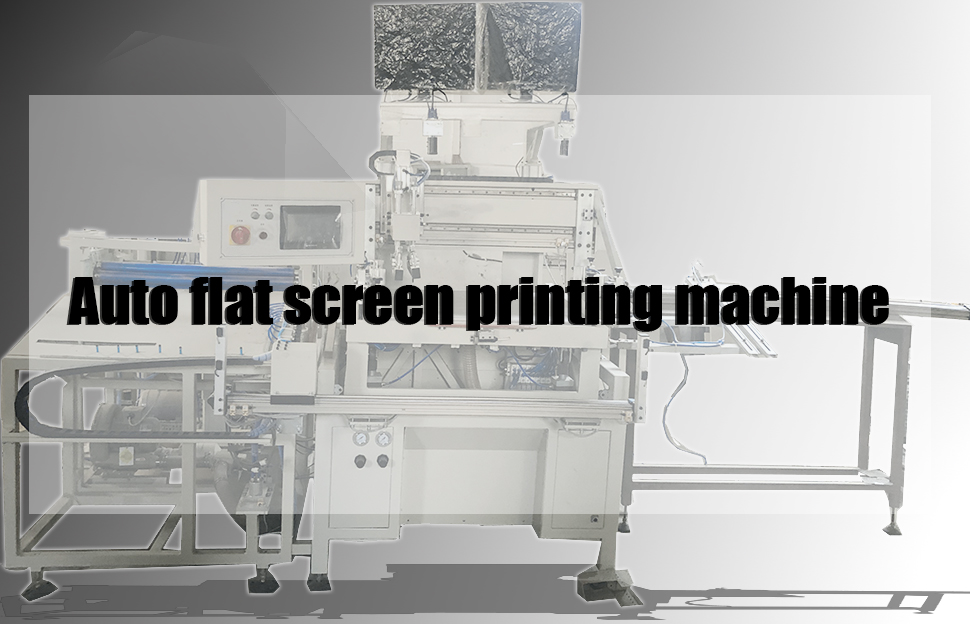

Auto flat screen printing machine with Dust electrostatic and positioning system

Product Description

Product Description

This is a high speed Fully Automatic Flat Screen Printing Machine, which are extensively used for printing on flat surfaces like PVC, Metal, Glass, Paper, Board and PCB.

These are highly cost effective as these require less power.

This screen printing production line can be placed in smaller workshop spaces.

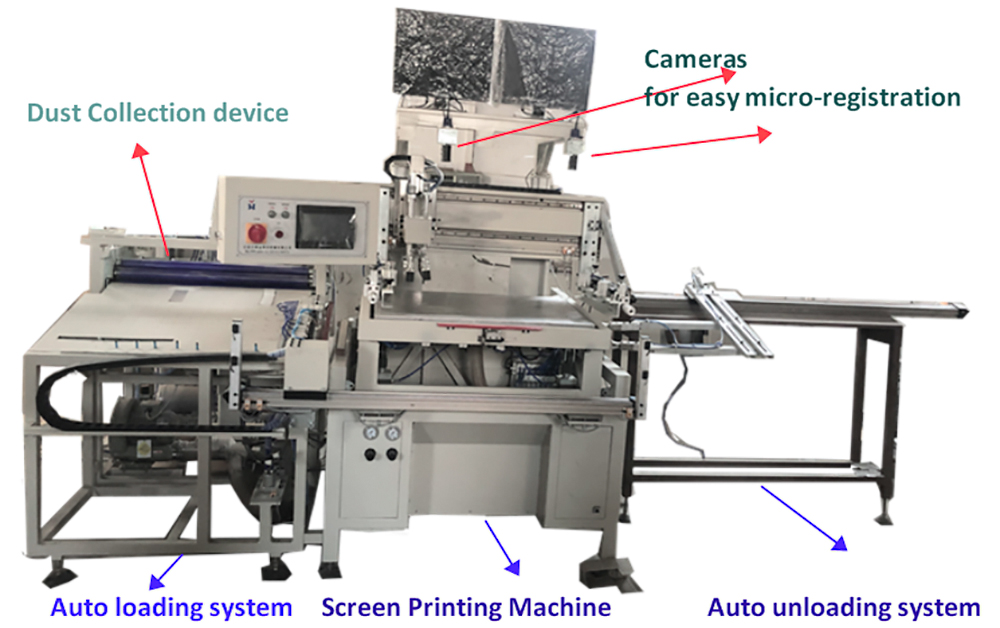

The machine is consist of three parts:

Automatic loading system —High precision Screen Printing Machine—automatic unloading system

Product Specification

|

Auto flat screen printing machine with Dust electrostatic and positioning system

|

|

|

Model |

JM-LRH5065 |

|

MAX Printing Area |

500*650mm |

|

Repositioning Precision |

<0.05mm |

|

Platform size |

590*860mm |

|

Max Frame Size |

750*1030mm |

|

Print thickness |

0.05~2mm |

|

Max Printing Speed |

900 pcs/h |

|

Degree of Squeegee blades |

0~30° |

|

Frame adjustment of vertically and horizontally |

+-10mm |

|

Advantage |

Dust electrostatic system + positioning system |

|

Power |

3N-50Hz 380V 3KW |

|

Gas source Pressure |

0.4-0.6 Mpa |

|

Dimensions(L*W*H) |

2300*1800*2200 mm |

|

Weight(kg ) |

900 |

Features

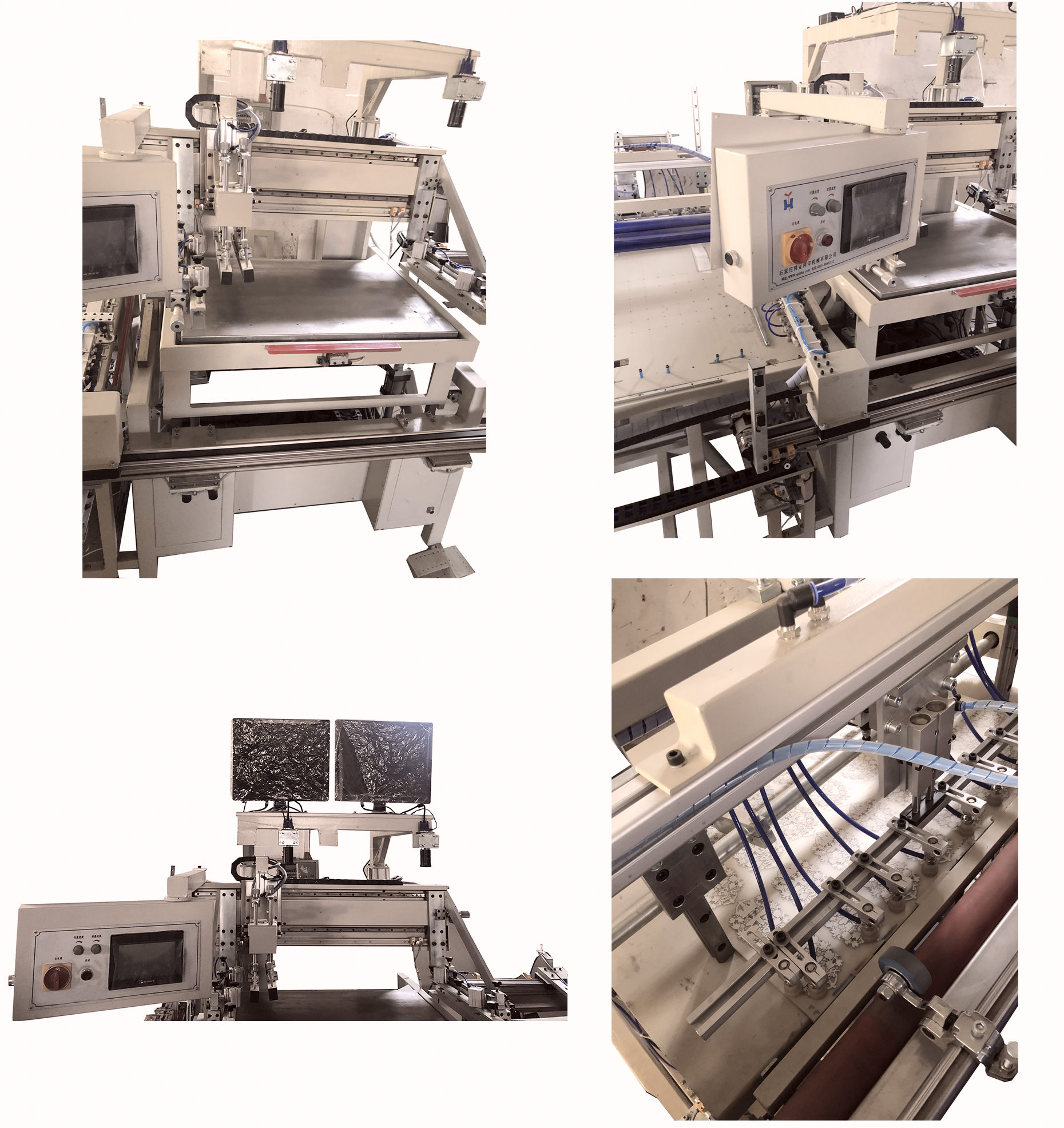

1.The platform can automatically lift,decline by electromotion.

2.The working table/platform is made of stainless steel with honeycomb for vacuum sorption

3.A registration pin is installed to keep precise registration and enssure the precision of repeat-printing is 0.05mm

4.The screen plate has support positioning, suitable for Precision multi-color printing

5.The screen plate can be adjusted front and back, left and right, and level location.

6.Power vacuum adsorption,make sure accurate color registration

7.Squeegee angle is adjustable

8.Adjustable left and right stroke. / front and back stroke.

9.Lifting structure is designed in double-pillars, high accuracy, stable operation

10.Constant pressure device of the ink blade, made sure the pressure in the printing is steady

11.Four digital auto-counter, calculate the printing quantity.

12.Touch screen with PLC controlled. Durable and simple maintenance

13.Working speed fast, stable and low noise

Application:

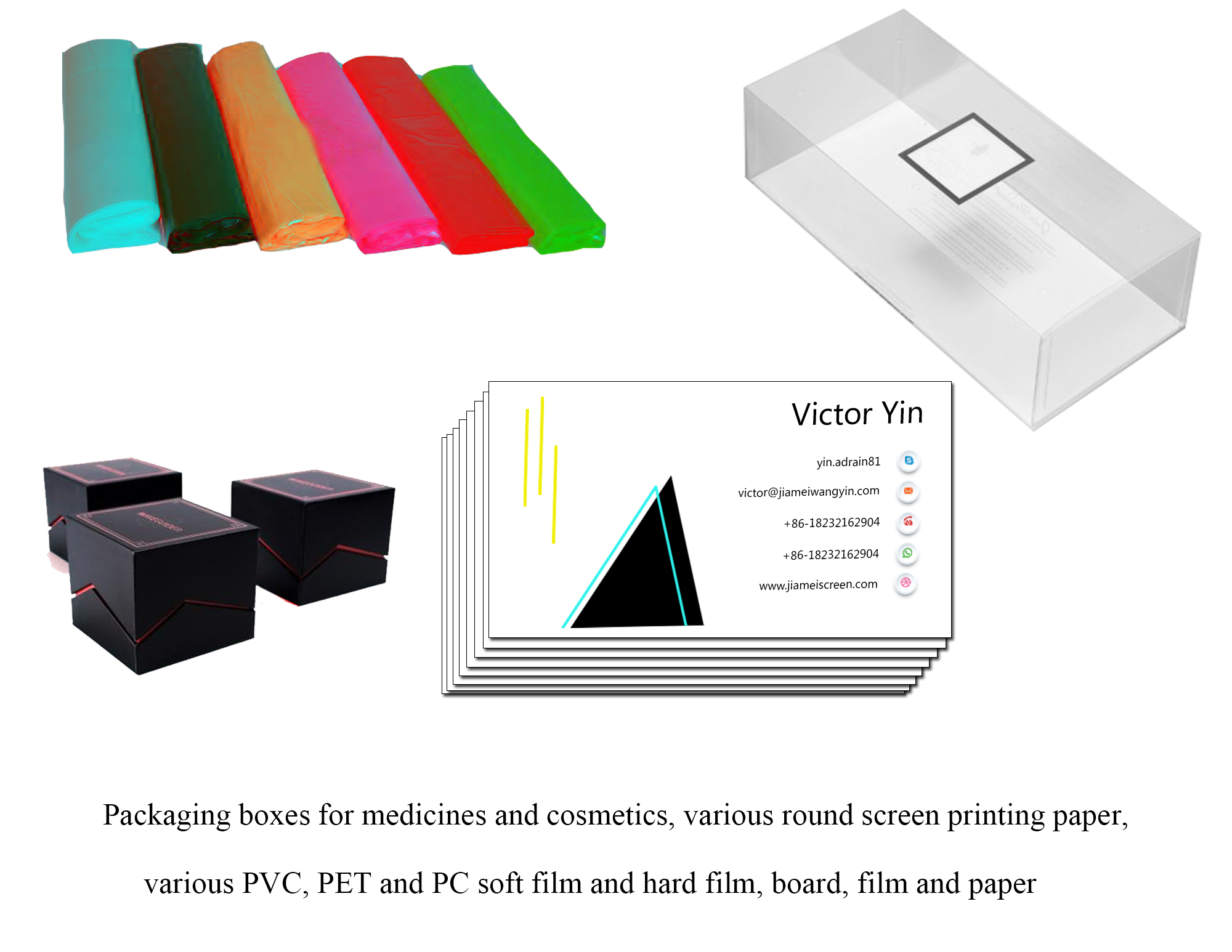

1)This silk screen printer series are widely used in the electronics, advertising, package printing, sports equipment, toys, stationary gifts, metal processing industries.

2)Suitable for printing on all kinds of flat materials, print on metal, wood, paper, plastics, membranes switch, PCB, PET, Playing, wedding, business and DC card, nameplate ,also printing on bags, non-woven fabrics, ceramic decals, glazing plate glass, light guide plate, PET heating transfer film, label and panel , refrigerator and air-conditioner decals, plastic sheet, and other products with the material of PVC, which have high requirement in overprinting.

3)Suitable for photo sensitive solder mask, PCB legend, ,FPC line, LGP, membrane switch, ceramic decal and packing decoration

4) The screen print of the film, card, board, and paper made of variety of basic material in different thickness. Such as the packaging box of cigarette, liquor, tea, medicine and cosmetics, various rotary screen-printing paper, all kinds of PVC, PET and PC soft films and hard films, boards, membrane and paper.