Free sample for Curing Dryer - silk screen printing vacuum exposure unit – Jiamei

Free sample for Curing Dryer - silk screen printing vacuum exposure unit – Jiamei Detail:

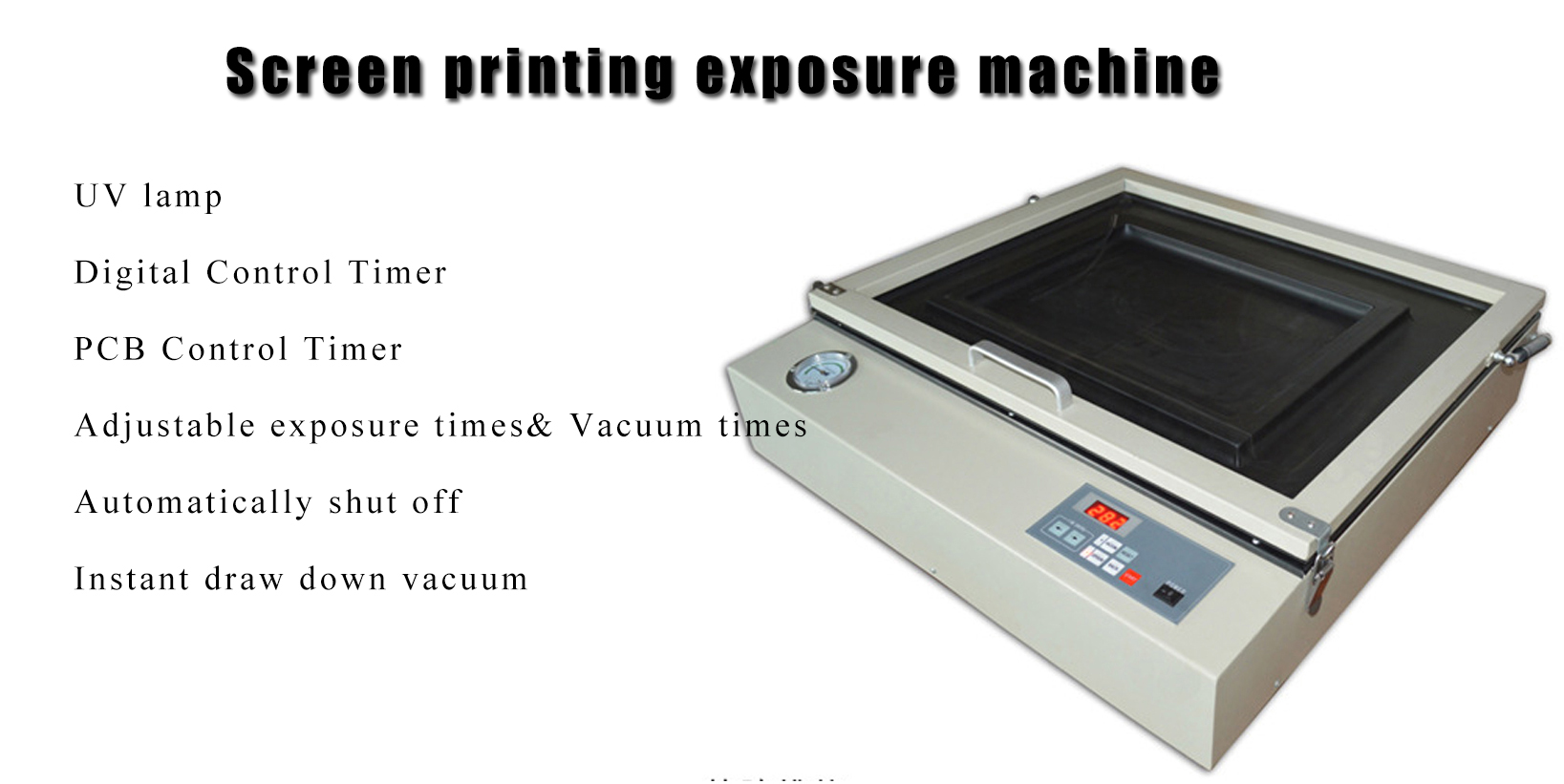

JM-EM6075 Vacuum Exposure Unit

The plate printing machine is a contact exposure imaging device used to make printing plates. It uses pressure (including atmospheric pressure and mechanical pressure) to make the original plate and the photosensitive plate closely fit, so that the image on the original plate can be accurately exposed through photochemical reaction. Made on a photosensitive plate. The printing machine is mainly composed of light source device, exposure chamber, vacuum chamber, electrical parts, machine base and other parts.

Product Specification

| JM-EM6075 Vacuum Exposure Unit | 110V/220V | Max.working area | • Light source:UV light |

| 50Hz, 400W | 24″ * 30″ | • Lamp power*amount: 20W*10pcs | |

| 600*750mm | • Digital display of exposure time setting | ||

| • Volume Weight : 60KGS |

Advantage

1. Choose high quality metal halid lamp. keep long life.

2. Reflect cover made by resist aging materials.

3.It can reach the vacuum state instantly, and save time for printing

4. Exposal time auto adjustment and controlling.

5. High vacuum degree, easy to transfer and copy fine lines

6. Automatic door of lamp shut off and turn on when exposure and finish ensure long life of lamp

7. High toughness Rubber Layer ensure Film closely cover with frame

8. We also can supply the different size of screen printing machine according to customer’s requirement

Announcements

1. Long time will not work, pull the plug.

2. Finished working after a version, according to the stipulation time open and close.

3. If screen frame with water, don’t use vacuum, otherwise the inhaled water will be rusted the vacuum pump.

4. Keep the worktable neat and dry, with soft and delicate cloth to clean after finishing work.

5. Keep in ventilated and dry place, far away corrosion items.

6. Do not keep it in high heat and humidity place.

7. Once turn off the lights, should be in a given time after 5 minutes (that is after cooling tube) to turn on the light, otherwise, it will reduce the working time of lamp.

8. light hand should press 1 second, don’t long hold, it’s too easy to burn out trigger

Working Principle

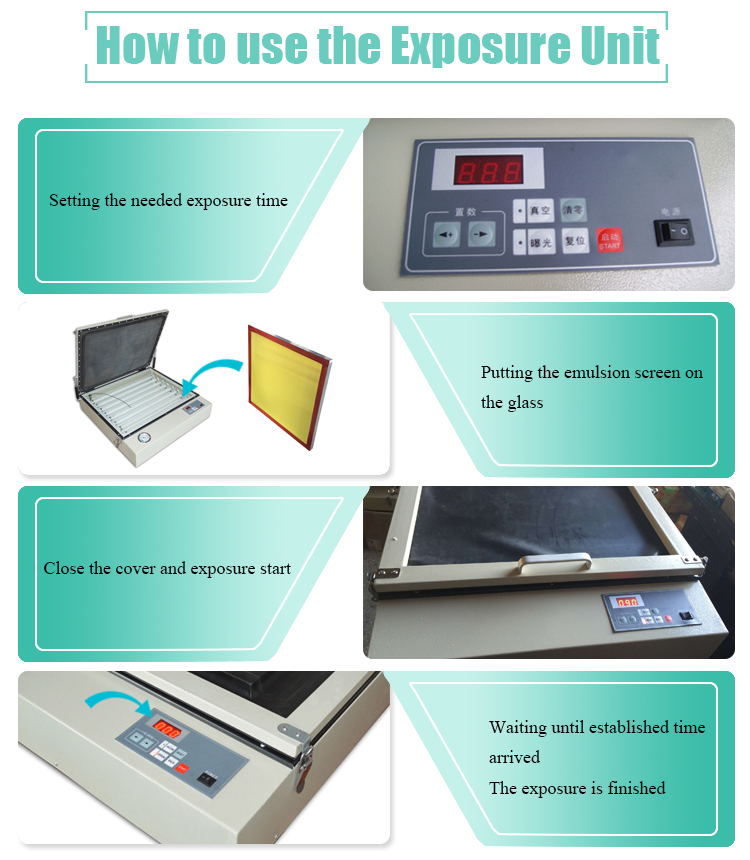

Screen printing screens are coated with a light sensitive emulsion using a scoop coater. When the emulsion is dry, place a positive print of your image on the screen. Once you burn the screen, the emulsion that did not get any UV will wash out of the screen exposing the tiny pin holes. The surrounding areas that were exposed to UV will be cured. Hence the ink will pass through screen onto your substrate.

Main Features

1. Rational design & easy operation: based on humanity and practicality principles, with the elaborate designed table type structure, it’s much easier for screen exposure with high precision.

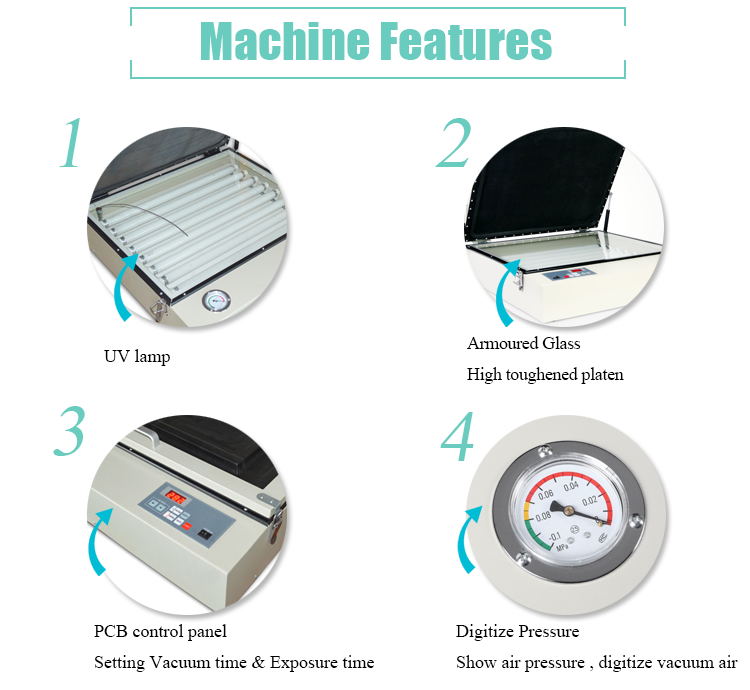

2.Independement settings of vacuum and exposure time with automatic memory function: The vacuum time and exposure time can be set up separately just according to actual requirements (setting ranges: 0-999 seconds); When exposure is finished, the power supply of the lamp will be automatically cut off, it will deflate and beep by itself, then please turn it off. When you need exposure again, just connect the power supply, then it will work automatically according to your former settings because of its automatic memory function.

3.Oilless vacuum pump with high quality is durable with no need for oil injection.

4. 8 pieces of special UV exposure lamps will guarantee a precise and even exposure effect.

5. The high strength toughened glass (thickness: 0.24”/6mm) is with high press resistance and not easily scratched. Besides, once broken, it will turn into pieces without sharp edges to avoid user’s injury.

6.All-metal construction & elegant appearance with advanced electrostatic paintings, easy to clean and no rust.

7.Excellent packing in study wooden case as a whole will guarantee a easy and safety transportation.

Product detail pictures:

Related Product Guide:

Back-to-back ninth-inning home runs doom Indians against Royals | Textile Screen Printing Conveyor Dryer

Best workout presents to buy in 2019 – workout presents buying guide | Flash Dryer Screen Printing

Our pursuit and enterprise aim would be to "Always fulfill our buyer requirements". We carry on to acquire and layout excellent quality items for the two our old and new clients and realize a win-win prospect for our shoppers in addition as us for Free sample for Curing Dryer - silk screen printing vacuum exposure unit – Jiamei , The product will supply to all over the world, such as: Morocco , Iraq , Lesotho , Now, we are trying to enter new markets where we do not have a presence and developing the markets we have now the already penetrated. On account of superior quality and competitive price , we'll be the market leader, be sure to don??¥t hesitate to contact us by phone or email, if you are interested in any of our solutions.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.